What is Control System?

AI Overview:

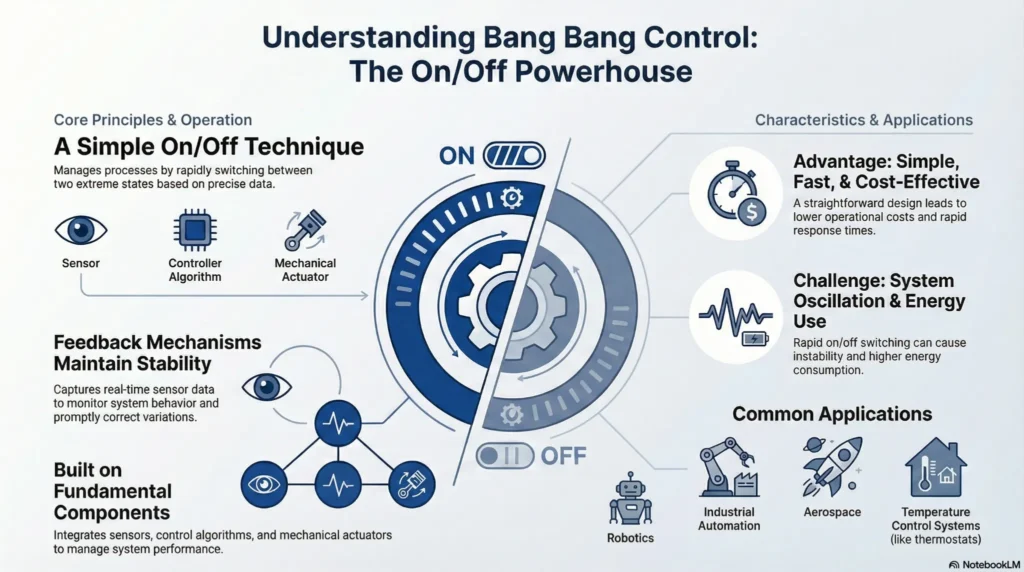

Bang Bang control systems use a simple on/off switching method to regulate processes quickly and efficiently. By reacting instantly when set thresholds are reached, they deliver fast response times, low maintenance, and reliable performance across applications like industrial automation, robotics, aerospace systems, and office equipment.

While their simplicity makes them cost-effective, challenges such as oscillations and energy use exist—driving interest in enhancements like AI, machine learning, and advanced sensors to improve stability, efficiency, and responsiveness in modern smart systems.

Understanding Bang Bang Control Systems: A Comprehensive Overview

Does the operation of your control systems fall short of your expectations? This article provides a comprehensive overview of bang bang control systems, detailing their basic definition, operational method, and practical applications. Readers gain insight into managing office equipment effectively and optimizing systems for improved performance. The content addresses common challenges in controlled environments and offers practical guidance to solve these issues.

Key Takeaways

- Bang Bang control systems rely on rapid on/off switching using precise data

- Feedback mechanisms adjust performance in real time to maintain system stability

- Simple design promotes low maintenance and reliable office equipment performance

- Machine learning and AI improve responsiveness and reduce energy consumption

- Enhanced sensors and actuators create high-quality data for optimal control

Defining Bang Bang Control Systems

Bang Bang control systems use a straightforward on/off technique that manages processes with rapid switching action. This method relies on precise data to regulate performance efficiently.

The control systems depend on an applied strategy where minimal input variations trigger a significant mechanical response. The technique incorporates an email address option for enhanced system notifications and monitoring.

In these systems, control actions are executed when specific thresholds are met, such as triggering a system when heat reaches a set value. The efficiency of this control method is based on reliable data inputs.

The applied principle in Bang Bang control systems offers a clear structure for decision-making. A supported mechanical design ensures the system’s responsiveness and efficient processing of data.

Historical Development of Bang Bang Control

The development of Bang Bang control systems began with fundamental studies in mathematics and log data analysis. Researchers focused on simple models that offered quick responses and basic feedback mechanisms.

Early experiments recorded the behavior of mechanical systems under continuous load, noting instances of fatigue and performance shifts; a table presents a structured timeline of these findings:

Subsequent advances improved the design by incorporating dynamic feedback allowing systems to adjust based on real-time log updates. These changes reduced component fatigue while improving overall control efficiency.

The integration of machine learning techniques refined the control response further, blending computational mathematics with practical feedback analysis. This transition marked a strategic improvement in early models.

How Bang Bang Control Systems Operate

Operating on simple on/off principles, Bang Bang control draws on control theory to manage processes. This section examines key components such as the thermostat and metal sensor, along with system constraint equations and feedback mechanisms, to offer practical insights for tuning performance.

Key Components of Bang Bang Control

Bang Bang Control systems rely on a few fundamental components that integrate modern electronics with principles from science and calculus. The design includes sensors and controllers that monitor motion and other environmental factors, resulting in rapid on/off switching managed through precise software algorithms.

The setup uses mechanical relays and digital interfaces to process control inputs with high accuracy. This configuration provides actionable insights by combining practical electronics knowledge, real-time data processing, and reliable software support for optimum performance in dynamic applications:

- Sensors for motion detection

- Calculus-based control algorithms

- Electronics circuits for data processing

- Software for system management

Feedback Mechanisms in Bang Bang Control

The feedback mechanism in Bang Bang control systems captures data from sensors to monitor system behavior in real time. This process involves components such as a valve that adjusts based on precise signal triggers and utilizes javascript for seamless integration of control algorithms, ensuring that any variations are promptly corrected.

Engineers rely on detailed data reports, similar to a pdf account of system performance, to fine-tune the responsiveness of the feedback loop. This approach offers clear insights into system behavior, providing practical examples that help businesses optimize managed IT services and office equipment performance.

Applications of Bang Bang Control Systems

This section addresses practical applications in industrial automation and process control, robotics and actuation systems, and aerospace and vehicle dynamics. It highlights how discrete mathematics supports seamless control, including air conditioning and proportional control, ensuring effective automation solutions. The insights provided offer business owners clear value in optimizing managed IT services and office equipment performance for enhanced operational efficiency.

Industrial Automation and Process Control

Industrial automation harnesses the bang bang control system to apply a simple yet effective algorithm that capitalizes on the heaviside step function for swift responses. This method aids in achieving optimal control in various processes by accurately adjusting velocity parameters and relying on core principles from computer science for real-time performance improvements:

- Utilizing sensor data for precise timing

- Implementing rapid on/off switching to maintain process stability

- Applying mathematical models to sustain consistent system performance

Process control in automation benefits from these systems by incorporating an algorithm that supports optimal decisions in industrial settings. The integration of computer science techniques with practical engineering principles ensures that velocity and force adjustments occur promptly, addressing operational challenges and enhancing the overall performance.

Robotics and Actuation Systems

Robotics and actuation systems benefit from a precise control mechanism that utilizes a Bang Bang approach for efficient operation. The system adjusts the setpoint for a furnace and displays data on the integral performance while a robot executes commands without delay.

The approach streamlines troubleshooting by integrating secure password protocols and real-time feedback for system optimization:

- Sensor-based adjustments for the furnace

- Accurate setpoint calibration

- Integral data monitoring for improved performance

- Real-time robot operation involving rapid on/off action

Aerospace and Vehicle Dynamics

The integration of Bang Bang control systems in aerospace and vehicle dynamics offers a robust solution for managing the engine’s performance during rapid condition shifts. The system’s precision helps maintain stability in engine operations, reducing wear and ensuring reliable responses across varying operational states.

This control approach supports critical engine functions by adjusting parameters in real time, which minimizes delays in response to sudden changes. The application of these systems in aerospace and vehicle dynamics provides businesses with actionable insights for optimizing engine performance in challenging environments.

Advantages of Bang Bang Control Systems

The system’s simple design ensures cost-effectiveness while delivering fast response times and precise control. This approach highlights ease of use and operational speed, setting the stage for detailed insights on simplicity, cost-effectiveness, rapid adjustments, and precise performance in subsequent sections.

Simplicity and Cost-Effectiveness

The straightforward nature of Bang Bang control systems makes maintenance and troubleshooting more manageable for businesses. This simplicity translates to lower operational costs, which benefits small and medium enterprises facing budget constraints.

Industry specialists point to the clear cost advantages these systems offer, noting that the minimal components reduce the need for extensive repairs. The cost-effectiveness of Bang Bang control systems supports streamlined operations for office equipment performance and managed IT services.

Fast Response Times and Precision

The system delivers rapid on/off control actions that optimize equipment performance in real-time, giving businesses clear insights into operational efficiency. Using straightforward switching techniques, the method supports managed IT services and office equipment reliability by processing sensor inputs instantly.

The precise mechanism ensures that any deviation in system parameters is corrected without delay, reducing downtime and maintenance issues. With fast response times and accuracy in data processing, the approach offers valuable support to firms managing critical office operations and technical services.

Limitations and Challenges of Bang Bang Control

System stability and oscillations, energy consumption concerns, and viable alternatives are key topics. The discussion highlights how limited control flexibility can lead to oscillations, increased energy use, and the potential benefits of alternate strategies. Each area offers practical insights, helping stakeholders understand the tradeoffs in managing office equipment performance effectively.

System Stability and Oscillations

The system’s rapid on/off switching can lead to sudden oscillations, presenting challenges for maintaining stable operations. Engineers often observe that frequent oscillations can affect performance consistency and may require additional adjustments to ensure stable behavior in managed IT services and office equipment.

Oscillations caused by minor fluctuations in sensor inputs demand careful calibration of system parameters. Stakeholders dealing with office equipment performance and cybersecurity solutions can benefit from fine-tuning control settings to minimize oscillation issues and improve overall responsiveness.

Energy Consumption Concerns

The system’s rapid switching can lead to higher energy usage during prolonged operations, which may be problematic for businesses seeking to manage operating costs effectively. Real-world observations indicate that optimizing sensor thresholds can help mitigate excessive power draw.

Industry experts note that fine-tuning the system’s calibration parameters contributes to lower energy consumption without compromising performance. Effective modifications to energy management practices provide a practical solution for businesses using managed IT services and office equipment.

Alternatives to Bang Bang Control Systems

Engineers often seek alternatives such as proportional-integral-derivative models, which provide a smoother response and reduce oscillations in controlled systems. This method supports managed IT services and office equipment performance by offering a more stable, less aggressive control strategy tailored for business environments.

The implementation of fuzzy logic control systems also provides a viable alternative, especially in settings where precision and gradual adjustments are required. This approach delivers actionable insights and practical benefits for businesses managing cybersecurity and office operations through improved system reliability and energy efficiency.

Future Trends in Bang Bang Control Technology

Integrating AI and machine learning refines the performance of Bang Bang control systems while advances in sensors and actuators upgrade detection accuracy. These improvements empower smart systems to execute rapid and precise responses, providing valuable insights for managed IT services and office equipment performance.

Integrating AI and Machine Learning

Integrating artificial intelligence with machine learning refines control responses in systems by automating adjustments based on real-time data. This application of smart algorithms in Bang Bang control systems offers practical benefits that address the needs of businesses managing IT services and office equipment.

Engineers use machine learning models to optimize sensor performance and improve feedback loops in control designs:

- Enhanced data processing accuracy

- Rapid response to environmental changes

- Optimized energy consumption rates

These improvements empower systems to operate efficiently, delivering faster adjustments and reliable performance under dynamic conditions.

Advances in Sensors and Actuators

Recent innovations in sensors and actuators offer improved accuracy and efficiency in Bang Bang control systems. These advancements support rapid data collection and seamless mechanical responses, ensuring optimal performance and reduced downtime. The developments provide practical benefits for businesses seeking reliable system management and real-time process monitoring:

Engineers observe that modern sensors and actuators bolster performance by delivering consistent, high-quality data essential for refining control algorithms. This progress helps reduce energy usage and maintenance issues in office equipment and managed IT services. Stakeholders benefit from actionable insights that support quick adjustments and secure operations in demanding industrial environments.

The Role of Bang Bang Control in Smart Systems

Bang Bang control systems play a key role in integrating smart systems by offering precise, rapid responses essential for modern office equipment performance. The approach supports robust managed IT services and cybersecurity solutions by providing reliable, real-time feedback that helps businesses maintain optimal operational efficiency.

Engineers rely on these systems to achieve secure, accurate control in dynamically changing environments. The method aids in fine-tuning smart systems for seamless communication and improved performance in critical infrastructure, ensuring that companies receive actionable insights into their data and system behavior.

Frequently Asked Questions

What defines a bang bang control system?

A bang bang control system operates with binary output actions, switching quickly between two extreme states to maintain desired process conditions reliably and simply.

When did Bang Bang Control develop historically?

There is no historical data regarding Bang Bang Control's development within the provided records from 1800 Office Solutions. Additional research is necessary to uncover its timeline.

How do bang bang systems function?

Bang bang systems function by rapidly switching electrical signals to control device operations, using precise pulse timing to manage activation and deactivation within office equipment and managed IT services.

What applications use bang bang control systems?

Bang bang control systems are applied in temperature regulation, robotics, and fluid management, offering simple on/off control useful in industrial automation and select office equipment calibration tasks.

What challenges do Bang Bang systems encounter?

Bang Bang systems face integration issues with modern protocols, outdated infrastructure complications, and network scalability limitations that affect overall business efficiency and risk management.

Conclusion

Bang Bang control systems are vital for achieving rapid, precise responses in various application areas such as industrial automation and managed IT services. Their straightforward design minimizes maintenance costs while maximizing process stability and data accuracy. The detailed analysis provided highlights the practicality of integrating sensors, real-time feedback, and even AI enhancements for improved system performance. Business owners gain actionable insights that support reliable operations and optimized performance of office equipment and cybersecurity solutions.