The Hidden Hardware Behind Smarter Offices

Custom PCBs as the Circuitry Behind Smart OfficesAI Overview:

Modern offices run smoothly thanks to custom printed circuit boards (PCBs)—the hidden hardware connecting lights, sensors, screens, and systems. These boards act like the office’s nervous system, managing power, data, and communication between devices. Custom PCBs boost efficiency, reliability, and energy savings while enabling smarter automation. Behind every seamless meeting and self-adjusting light lies precise engineering—and a touch of human creativity.

The Hidden Hardware Behind Smarter Offices

You’ve probably noticed how offices just… work now. Lights adjust on their own. The meeting invites sync from your laptop to the big screen. The printer never seems to run out of toner at the worst possible moment. Behind that quiet harmony sits something you almost never see: the custom PCB that keeps everything connected.

Wait, What Exactly Is a PCB?

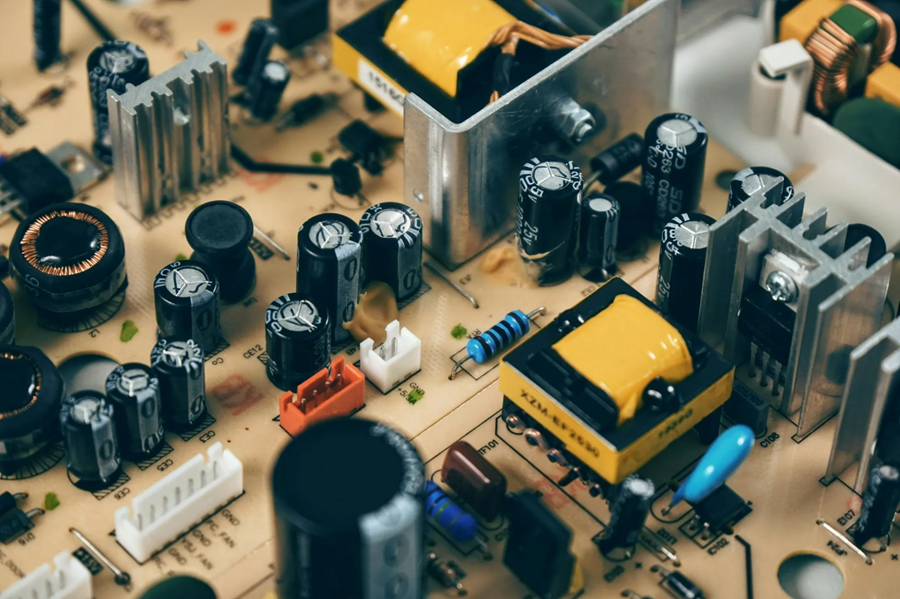

Think of a PCB—printed circuit board—as the nervous system of every smart device you use. It’s a flat green board with thin copper lines and little components soldered on top. Each trace is like a nerve fiber, carrying signals and power where they need to go.

When it’s custom-built, it does more than just connect parts. It defines the personality of the device itself. That’s why two sensors that look identical might behave completely differently—because their PCBs were designed for different “brains.”

The Modern Office Is Basically a Living Circuit

Walk through a workspace today, and it’s buzzing with invisible signals. Your badge opens the door using RFID. The HVAC system talks to motion sensors. Even your coffee machine might log data about energy use.

What ties all this together isn’t just software or Wi-Fi; it’s hardware that interprets and transmits those signals precisely. Without custom PCBs, none of these micro-communications would happen smoothly.

It’s a bit poetic, really—tiny copper lines helping humans collaborate better.

Why “Custom” Matters

Mass-produced PCBs are fine for basic devices. But in offices where systems must talk seamlessly, “fine” doesn’t cut it. Each piece of tech has its quirks: different voltages, sizes, thermal needs. Custom PCBs are built around these details, ensuring everything operates without interference or energy loss.

Here’s the thing: offices aren’t static anymore. They evolve—adding sensors, integrating new meeting tools, adapting to hybrid setups. A customized PCB lets those systems scale without rebuilding the entire network. It’s the difference between a store-bought suit and one that actually fits your shoulders.

From Desks to Data Centers: Where PCBs Hide

If you could peel back the casing of every office gadget, you’d find PCBs almost everywhere:

- Monitors and docking stations control signal flow and power regulation.

- Printers and scanners rely on precise PCB timing to sync motors and sensors.

- IoT sensors detect temperature, air quality, or occupancy using microcontrollers on specialized PCBs.

- Conference systems convert voice and video signals with PCB-driven processing chips.

- Networking gear—routers, switches, access points—are essentially layers of PCB boards managing traffic.

It’s wild to realize that the quiet efficiency of an office morning depends on thousands of circuits talking at once.

The Art of PCB Design: Tiny, Precise, and Creative

Designing a PCB isn’t just engineering—it’s part puzzle, part poetry. Designers map signal paths, control heat dissipation, and sometimes even shape the board around odd enclosures.

In smarter offices, PCB design also considers electromagnetic interference (EMI). Think about how many wireless devices operate near each other. A single design flaw could cause a sensor to glitch or a display to flicker.

So, engineers use simulation tools, layered routing, and specialized materials to avoid interference. It’s a meticulous craft that balances creativity with constraint—like composing music with electrical notes.

How PCBs Power Workplace Intelligence

Every “smart” function in an office starts with data. Sensors collect it, processors interpret it, and systems respond. Custom PCBs manage this entire process.

For example, a smart lighting system might use:

- A sensor PCB to detect motion and brightness.

- A control PCB that runs energy-saving algorithms.

- A communication PCB linking to the office’s central server.

Each of these boards talks to the other, sometimes in microseconds. And the best part? Employees barely notice—it just works.

Energy Efficiency: The Silent Superpower

Let’s talk about sustainability for a second. Offices are under pressure to lower energy use without compromising comfort. Custom PCBs help here too.

By optimizing power delivery and signal timing, they reduce wasted electricity. A well-designed board can extend device life and cut heat generation. Multiply that by hundreds of devices in an office, and the impact becomes tangible.

It’s not the glamorous side of green tech, but it’s one of the most effective.

The Reliability Factor

You know that feeling when the Wi-Fi drops right before a presentation? Reliability matters.

Custom PCBs are tested for vibration, heat, and electrical noise to ensure they don’t fail under stress. Manufacturers like OurPCB even run flying probe and impedance tests, confirming each trace performs within micro-scale tolerances.

In short, these boards are built to keep calm under pressure—something every office could learn from.

Smarter Offices, Smarter People

Here’s a fun thought: as our offices get smarter, so do we. Not just in convenience, but in how we think about connection.

Hardware like custom PCBs reminds us that intelligence isn’t only digital. It’s physical. It’s embedded in the tools that quietly make collaboration effortless.

And honestly, there’s something comforting about that. The more we automate, the more we rely on things we can’t see. Yet behind all that tech, there’s still a trace of human design—a person who decided where each copper line should go.

What’s Next for Office Hardware?

We’re entering a phase where the line between personal and office tech blurs. Laptops link to AI assistants. Desks have embedded charging surfaces. Walls carry temperature sensors inside their paint layers.

Each new step requires boards that can handle more functions in smaller spaces. Think flexible PCBs bending around corners or multi-layer ones managing dozens of signals at once.

Soon, your desk could have a brain of its own, optimizing your workspace before you even sit down.

The Human Touch Behind the Circuits

Despite all this talk of automation, there’s still something very human about custom PCBs. Each board starts as an idea—someone thinking, “What if this device could do more?” Then it becomes a layout, a test, a soldered prototype.

The process mirrors creativity itself: trial, feedback, and revision. In a sense, these boards are physical expressions of imagination turned practical.

So next time your meeting room connects without a hiccup or your lights adjust just right, maybe take a quiet moment to thank the invisible engineers who made that possible.

Wrapping It All Together

Modern offices may look simple on the surface, but underneath lies a web of intentional design. From IoT sensors to complex automation systems, custom PCBs form the backbone of every interaction. They’re small, quiet, and unassuming—but they power the very rhythm of our workdays.

The smarter our offices become, the more vital that hidden hardware will be. It’s not just about technology keeping pace; it’s about craftsmanship, precision, and the subtle art of connection.