What Is Printer Ink Made of? A Detailed Look Inside

What Is Printer Ink Made of?

Printing is a technology that has shaped the way we communicate and document information for hundreds of years. Printer ink is a crucial component in this technology, and it’s made up of many different ingredients. Understanding what these ingredients are and how they work together gives us insight into how printers have developed over time.

Printer ink is made up of a combination of pigments, dyes, resins, and additives. Pigments are typically carbon black, and dyes can be either organic or inorganic. The resins and additives are used to bind the ink ingredients together and to give the ink its desired consistency and color. In the past, inks were made with linseed oil, soybean oil, and petroleum.

But today, more modern inks use petroleum distillate, varnish, and solvents as base ingredients. To create a specific color, printer manufacturers use titanium dioxide, Peacock Blue, Yellow Lake, Diarylide Orange, and Phthalocyanine Green pigments.

What Is Printer Ink?

Transitioning into the next topic, it is important to understand what printer ink is and how it works. Printer ink is a liquid made from a combination of oil, dyes, pigments, chemicals, carbon black, resins, and varnish. This mixture is then sprayed onto paper, allowing the ink to adhere to the paper and create a high-quality print. The type of printer determines the type of ink used, with inkjet printers typically using CMYK (cyan, magenta, yellow, and black) and laser printers using toner. The ink is then further refined with drying agents, such as organic or inorganic compounds, and additives like titanium dioxide, to give it shine and fade-resistance.

Printer manufacturers recoup the cost of the printer by selling you ink or toner cartridges. While the cost of a printer may seem low, the price of printer ink often outweighs the cost of the printer in the first place, as it is more expensive to buy new ink cartridges than it is to buy a new printer. Printer ink cartridges need to be tailored to a specific printer model in order to allow the ink to flow well and yield high-quality printing.

What Is Printer Ink Made Of?

In the past, the components of printer ink were quite simple. It was traditionally made from carbon black and varnish, a type of paint made from linseed oil and sulfuric acid. However, now, the composition of printer ink has become far more complex. Today, printer ink is typically composed of a mixture of pigments, resins, solvents, and additives. The types of ink used in printers vary considerably, based on the printer model and the type of printing method used.

Inkjet printers, for example, use liquid ink, while laser printers use a dry powder called toner. Both types of printers require a certain amount of ink in order to produce high-quality printing, and the amount of ink is determined by the properties of the ink and the printer manufacturer. For example, Epson printers use a specific type of ink that is similar to paint in composition and can produce a wide range of colors.

The majority of printer ink is composed of a pigment or dye, such as carbon black, which gives the ink its color. In order to allow the ink to flow well and adhere to the surface during printing, it also contains various additives, such as resins, solvents, and drying agents.

How Are the Different Colors Formed?

The formation of different colors is a complex process that begins with the base ingredients of printer ink. Printer ink is usually composed of oil and pigment. The oil serves as the vehicle that carries the pigment to the paper. The oils used in inkjet printers are either linseed oil or soybean oil, and those used in laser printers are petroleum distillates. The pigment is the main component that gives the ink its color. It can be either organic or inorganic; organic pigments are derived from plants and inorganic pigments are synthetic.

Ink manufacturers use various dyes and pigments to create the different colors. The most common printer ink colors are cyan, magenta, yellow, and black, but there are many other shades that can be created by combining the four primary colors in different proportions. For example, peacock blue is a mix of cyan, magenta, and yellow, while titanium dioxide is used to create a white color. Other colors that can be created using different mixes of inks include diarylide orange, phthalocyanine green, and yellow lake.

In addition to the pigments, other additives are added to the ink to give it the desired properties. These can include drying agents, varnishes, and solvents.

Different Types of Printer Ink

Dye-Based Ink

- Composition: Dye-based inks are made from colorants that are fully dissolved in a liquid.

- Characteristics: They offer bright, vibrant colors and are excellent for high-quality photo prints. However, they can be less UV-resistant and more prone to fading over time compared to pigment-based inks.

- Uses: Ideal for photo printing and applications where color vibrancy is crucial.

Pigment-Based Ink

- Composition: These inks contain tiny particles of colorant suspended in a liquid.

- Characteristics: Pigment-based inks are more resistant to fading, water, and UV rays. They are less vibrant compared to dye-based inks but offer better longevity.

- Uses: Commonly used for printing documents, fine art, and other applications where print longevity is important.

Solvent Ink

- Composition: Made with oil-based or solvent-based carriers.

- Characteristics: These inks are durable, water-resistant, and adhere well to a wide range of materials. They emit volatile organic compounds (VOCs) and require proper ventilation.

- Uses: Often used for outdoor signage, banners, and billboards.

Eco-Solvent Ink

- Composition: A gentler version of solvent inks with fewer VOCs.

- Characteristics: Eco-solvent inks are less harmful to the environment and human health. They are durable and resistant to outdoor elements.

- Uses: Suitable for indoor and outdoor graphics, signage, and vehicle wraps.

UV-Curable Ink

- Composition: These inks are cured and hardened when exposed to ultraviolet light.

- Characteristics: They are very durable, resistant to scratching, and suitable for both indoor and outdoor use. UV inks can print on a wide range of materials.

- Uses: Used in industrial printing and for products like banners, backlit signage, and wallpapers.

Sublimation Ink

- Composition: These inks turn into gas under heat and pressure, infusing into materials like fabric or coated ceramics.

- Characteristics: Sublimation inks offer vibrant colors and are permanent once transferred. They work only on specific types of materials.

- Uses: Commonly used for fabric printing, such as garments and flags, as well as for items like mugs and phone cases.

Water-Based Ink

- Composition: Primarily made from water as the solvent. They can be either dye or pigment-based.

- Characteristics: Generally safer and more environmentally friendly. They are not as durable as solvent-based inks.

- Uses: Often used in desktop inkjet printers for general and photo printing.

Each type of ink has its specific benefits and drawbacks, making them suitable for different printing needs and surfaces. The choice of ink depends on the required quality, durability, and the material being printed on.

Why Is Printer Ink so Expensive?

The intricate process of creating printer ink is no small feat. From the black ink used in laser printers to the colored inks used in inkjet printers, a variety of printing inks are used to produce the desired results. Writing ink, which is used in pens, and printing ink, which is used in printers, is made differently. The color of the ink, the mechanical properties of the ink, and the thickness of the ink all play a role in the printing process.

Manufacturers use a combination of carbon black and varnish, along with additional ingredients such as resins, dyes, solvents, and drying agents, to create ink. Carbon black is a type of pigment, similar to paint, that is mixed with a varnish made from either linseed oil or soybean oil and petroleum distillates. This mixture is then combined with a carrier, such as water, to allow for the ink to flow.

Inkjet printers typically use aqueous (water-based) inks that are made from a combination of organic or inorganic pigments and additional components. These inks are designed to adhere to the paper surface during printing, and they must have the right mechanical properties to allow for the ink to flow well.

What Is Printer Toner?

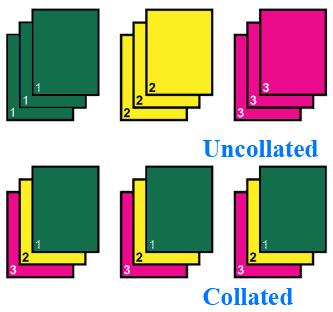

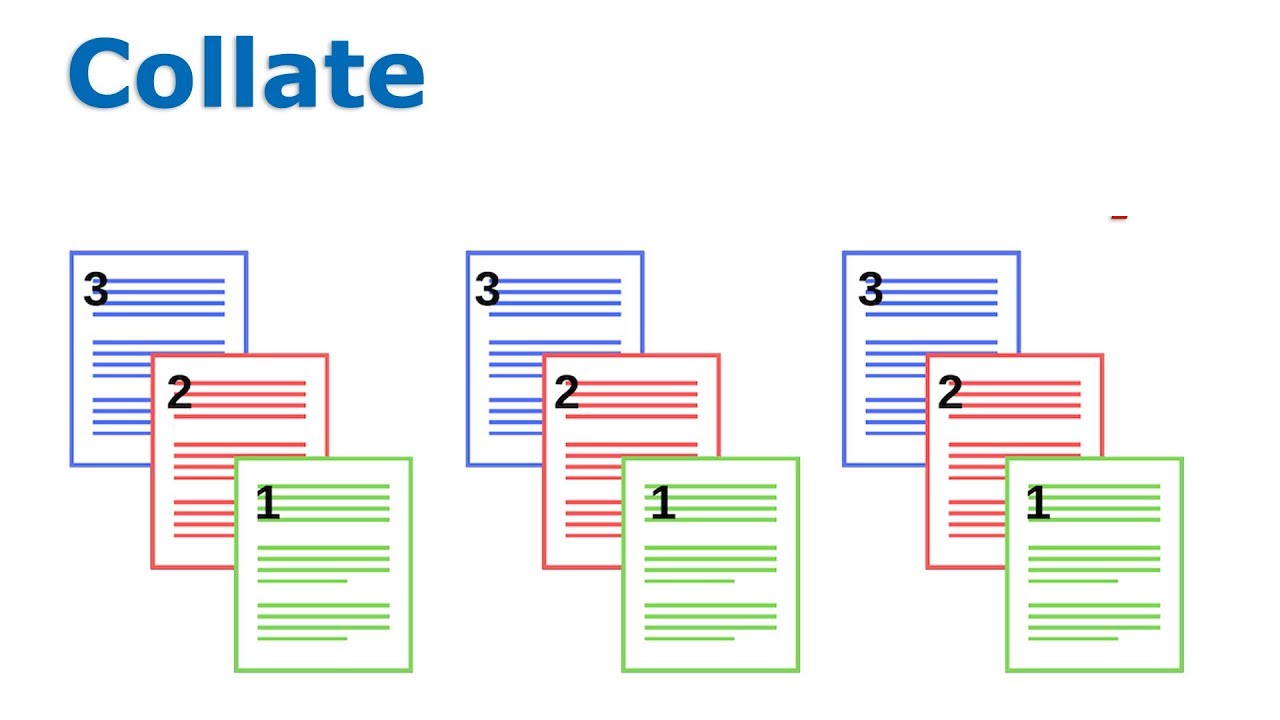

With the expense of printer ink, it’s no wonder that many people are beginning to consider alternative options. Printer toner is one of those alternatives. As opposed to ink, which is a liquid, printer toner is a fine powder that is used in laser printers, photocopiers, and multifunction printers. This powder is composed of finely ground plastic, silica, and various organic compounds like iron, chromium, and zinc.

Using toner results in better print quality and faster printing speeds, making it a popular choice for businesses and commercial applications. Plus, toner cartridges won’t dry out like ink cartridges, making them more cost-effective in the long run. When the primary colors of C, M, and Y are combined, printers can create the whole spectrum of color, and mixing all three gives an imperfect black or a perfect grey.

Ink is made from a variety of components, including carbon black and varnish, which is used to bind the ink ingredients together and allow the ink to flow well. Inks also contain numerous additives that give it the desired mechanical properties and allow the ink to adhere to the paper. Ink is usually oil-based, but there are also water-based inks that are used in some printing processes.

How Toner vs. Ink Adheres to Paper

The difference between how toner and ink adhere to paper is a complex one, but understanding it is essential for choosing between the two types of printing. Ink is the liquid that is used in an inkjet printer; it is manufactured using a combination of dyes, pigments, and other chemicals. Toner is a powder that is used in laser printers, and it is made up of carbon black, wax, and other substances. Both ink and toner cartridges are sold separately, and the quality of the ink can have a significant impact on the life of the printer.

The base ingredient of printer ink is usually oil, either linseed oil, soybean oil, or petroleum. It contains numerous additives that are used to alter its color, texture, and viscosity. This allows the ink to flow well and to adhere to the paper during the printing process. Different types of ink are used in different types of printers, and printer manufacturers can recoup the cost of the printer by selling you ink or toner cartridges over the life of the printer.

Inkjet printers typically use ink that is manufactured using a combination of dyes and pigments, while laser printers use toner, which is a powder made up of carbon black and varnish.

Conclusion

Traditional ink has been around for centuries, with the first printing press invented in the mid-15th century. Today, printer ink is made up of a combination of pigments, dyes, and resins that are manufactured into tiny droplets and then applied onto paper or other substrates. The components of printer ink can vary depending on the type of ink and the desired effect. Inks can be either organic or inorganic, and the type of printer used will dictate the type of ink used. For each type of printer, there are different types of ink that are tailored to that specific printer.

Printer manufacturers are able to recoup their costs of selling you the printer by also selling you ink or toner. The cost of printer ink can be expensive, but the quality of the ink and its ability to adhere to the paper over the life of the printer is worth it. Different types of printers require specific types of ink, so it is important to match the printer model to the ink type in order to get the best printing results.