What is baffle?

AI Overview:

This article explains what a baffle is, how it functions, and why it is essential in acoustic, fluid, and mechanical systems. It explores different baffle types, materials, and applications—particularly in office and industrial equipment—showing how baffles improve noise control, system stability, and performance. Readers also gain practical guidance on installation, maintenance, and real-world use cases that demonstrate how baffles reduce interference, enhance efficiency, and support reliable long-term operations.

Understanding Its Role and Applications

Have you ever questioned the role of a baffle in equipment performance? This article explains what a baffle is, its function across various systems, and examines different types used in office solutions. Readers gain practical insights that can help them better understand equipment design and resolve maintenance issues. The content targets business owners seeking clarity on baffle applications and benefits in office equipment maintenance.

Key Takeaways

- baffles improve noise control by directing sound paths in office and industrial systems

- quality materials and design ensure consistent energy distribution in equipment setups

- regular maintenance and proper installation keep baffles performing effectively

- case studies show baffles reduce interference and support smoother operations

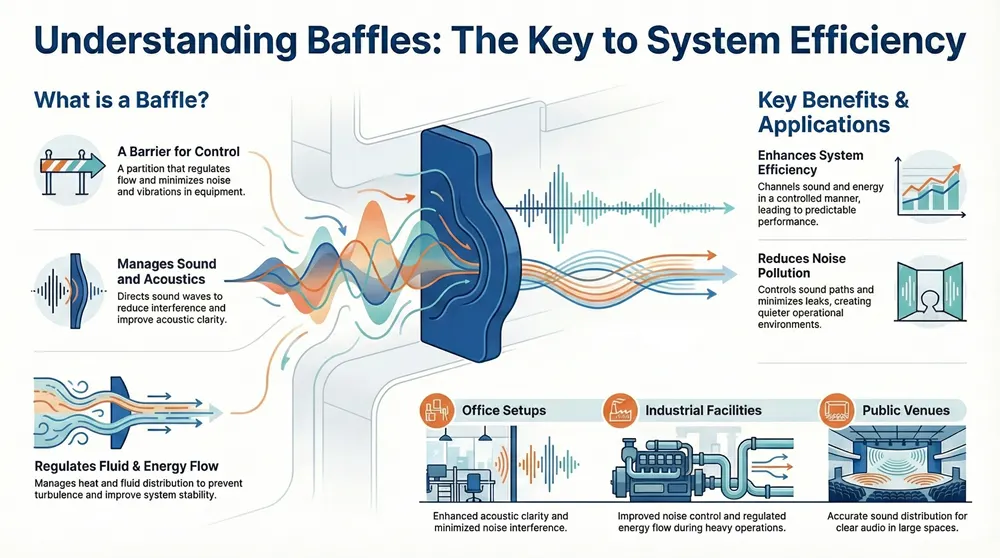

What Is a Baffle and Its Definition

This section outlines how baffles differ from similar components in loudspeaker setups with clear adjective descriptors. It explains common materials used for baffles and offers practical vocabulary to remove confusion, ensuring readers never balk at grasping its role.

Distinction Between Baffles and Other Similar Components

The distinction between baffles and other similar components lies in their unique design and function; baffles provide an essential barrier that minimizes sound interference, similar to how a glass partition might block unwanted noise. This design feature separates and directs sound, offering clear feedback and supporting the precise language of acoustic engineering, often explained in French idiom during technical discussions.

Other components in loudspeaker setups may prioritize amplification or dispersion of sound, but baffles specifically focus on isolating and channeling audio for better performance. Professionals appreciate this engineered separation for its effectiveness in controlling feedback and ensuring that every nuance is unmistakable, enhancing the overall language used in system calibration.

Common Materials Used for Baffles

Baffles often use sturdy materials to maintain a consistent flow of sound while managing fluid vibrations. The selection includes substances that meet strict quality standards as understood in the Scots language and informed by old norse design principles.

Manufacturers opt for materials such as engineered gravel composites to support efficient audio distribution, ensuring dependable performance during system calibration and testing:

- Engineered composites for acoustic stability

- Gravel-based panels for shock absorption

- Materials tested under fluid dynamic conditions

The Function of Baffles in Different Systems

Baffles play a key role in acoustic setups, fluid dynamics, and engineering applications. This section provides a clear synonym for their function across systems. It explains how baffles, made sometimes of plastic or foil, contribute to effective sound control and system stability, underscoring the importance of proper grammar in technical documentation to avoid any unintentional fraud in performance claims.

Role of Baffles in Acoustic Applications

Experts recognize that in acoustic applications, baffles serve as critical components that refine sound quality and minimize interference. This noun, often defined in wiktionary, functions as an engineered barrier, much like an effective advertisement in clarity, directing audio precisely where it is needed.

Industry specialists apply baffles to deliver clear acoustic performance by strategically isolating sound waves. These components offer tangible solutions to noise control issues, merging technical precision with practical expertise to address common challenges in sound management.

Importance of Baffles in Fluid Dynamics

The use of a baffle in controlling fluid dynamics significantly improves system stability and efficiency by managing the distribution of heat and sound. The design minimizes turbulence that can reach the ceiling, ensuring that the system does not confuse operators with erroneous readings during diagnostic tests.

The application of baffles in fluid systems contributes to a controlled environment where heat is managed efficiently while allowing clear sound signals to be maintained. This strategic integration prevents a build-up of energy that could otherwise confuse system calibrations and offers a reliable solution for maintaining operational consistency.

Baffles in Engineering and Machinery

Baffles in engineering and machinery play a critical role in managing system performance, ensuring that components work efficiently and effectively. The specialized design acoustically and mechanically isolates operations similar to how a well-maintained stove in Scotland supports optimal heating, while the correct pronunciation of technical terms, akin to learning a transitive verb from an online etymology dictionary, aids in clear communication among professionals.

Engineers incorporate baffles to regulate airflow and vibrations, thereby enhancing overall system reliability and minimizing disruptive motions. Expert insights in the field show that precision in terminology and practical application, whether discussing machinery or addressing industry standards, reinforces the technical framework and benefits stakeholders across various operational environments.

Types of Baffles and Their Specific Applications

This section covers static baffles used as a wall to reduce noise, adjustable baffles that offer participle flexibility for varied applications, and specialized baffles designed for unique environments. Industry insights show the baffled systems receiving attention similar to featured reports in los angeles times and reference etymology influences, ensuring clear and useful guidance for practical applications.

Static Baffles and Their Uses

Static baffles provide a reliable solution for minimizing sound interference and managing energy in various installations. Professionals note that much like the simple construction of “english english” language, the static design functions as a steady verb in acoustic setups, offering clear control over sound behavior. The concept of static baffles often appears as a puzzle that industry experts solve by aligning design with practical performance.

These components are integral in systems where stability and consistent energy distribution are paramount. The clear application of static baffles ensures that the intended behavior of sound isolation remains precise, similar to how a verb clearly defines an action in “english english”. Observations reveal that healthcare, manufacturing, and office environments benefit from the predictable performance and practical usage of static baffles.

Adjustable Baffles for Versatile Applications

Adjustable baffles offer a flexible option for businesses that need to modify sound control settings. This adjustment capability allows for tailored performance in varying office and industrial environments, ensuring that systems can settle into optimal operation quickly.

Industry experts note that adjustable baffles deliver reliable control over acoustic environments with practical ease. Their design supports necessary changes in setup configuration, meeting the demands of evolving operations and maintaining consistent service quality.

Specialized Baffles for Unique Environments

Specialized baffles designed for unique environments provide tailored solutions where traditional components may fall short. These components support optimal performance in areas with unusual acoustics or environmental restrictions, ensuring that sound management fulfills both technical requirements and operational needs:

Industry experts note that unique environments require specialized configurations to maintain system integrity and clear sound performance. The effective use of these baffles addresses both operational challenges and environmental factors, offering practical benefits for organizations looking to optimize their audio systems.

Benefits of Using Baffles in Various Contexts

System efficiency improves with baffles, which streamline operations across applications. Proper baffle design reduces noise pollution, ensuring offices and industrial setups perform better. Additionally, reliable baffle placement enhances operational performance in heavy-duty environments, resulting in sustained system integrity and clear audio feedback for users.

Enhancing System Efficiency With Baffles

Industry specialists observe that baffles boost system efficiency by channeling sound in a controlled manner, thus ensuring that operational performance remains stable and predictable:

Experts in managed IT services and office equipment note that strategically implemented baffles lead to better sound management, reducing downtime and operational challenges, which supports higher system reliability for the business environment.

Reducing Noise Pollution With Proper Baffle Design

Proper baffle design significantly cuts down on noise pollution by controlling sound paths and reducing unwanted interference. Clear and precise baffle configurations help stabilize audio distribution, which benefits office environments and industrial spaces alike.

A well-planned layout using quality baffle materials effectively separates noise sources and minimizes sound leaks:

This configuration offers practical solutions for businesses seeking to manage noise effectively, reducing distractions and enhancing operational performance.

Improving Performance in Industrial Settings

In industrial settings, baffles significantly boost performance by streamlining machinery operations and reducing disruptive vibrations. The use of quality baffles directly contributes to consistent energy flow, which improves overall equipment efficiency and lowers downtime due to mechanical disruptions.

Engineers observe that strategically placed baffles play a crucial role in managing noise and stabilizing system performance in heavy-duty environments. This practical application addresses common operational challenges and supports smoother workflows in industrial applications for better long-term reliability.

Installation and Maintenance Guidelines for Baffles

Proper baffle installation, routine upkeep, and troubleshooting common issues form the core topics. The section outlines clear steps for correct baffle placement, practical maintenance practices to ensure consistent performance, and methods to identify and resolve minor problems. This guidance equips professionals with practical insights to maintain system stability and efficiency efficiently.

Steps for Proper Baffle Installation

Professionals follow clear procedures when installing baffles, ensuring that each component is securely placed according to the manufacturer’s guidelines. They verify alignment and orientation to maintain optimal performance and system stability, addressing potential issues with precision during the setup process.

Skilled technicians emphasize calibration and quality control during installation, routinely checking that the baffles provide effective noise control and energy flow management. This careful approach minimizes operational downtime and supports consistent performance across environments.

Routine Maintenance Practices for Optimal Function

Routine maintenance practices are vital to the consistent performance of baffles in office equipment and industrial setups. Technicians perform regular inspections and cleaning to remove accumulated debris, ensuring that each baffle continues to deliver reliable noise control and optimal energy distribution.

Skilled professionals schedule periodic evaluations to check for alignment issues and any signs of wear. These maintenance practices help prevent minor problems from escalating, leading to improved system stability and extended equipment life.

Troubleshooting Common Baffle Issues

Expert technicians note that when troubleshooting baffle issues, it is important to inspect for physical misalignment or visible wear. They ensure that all components are securely fixed and that connections remain intact, monitoring any signs of vibration or noise interference that could affect performance in office equipment setups.

Industry professionals advise that regular inspections and cleaning help resolve minor issues related to dust buildup or loose fittings. They recommend a systematic approach to evaluating each baffle, ensuring clear operation in systems that support managed IT services and high-frequency copiers and printers.

Case Studies of Baffles in Action

Industry experts examine successful implementations in acoustic design, innovative uses in marine engineering, and lessons learned from industrial applications. These case studies provide practical insights that clearly illustrate how baffles improve sound control and system stability in diverse environments. The following detailed examples offer expertise directly relevant to managed IT services and office equipment performance.

Successful Implementations in Acoustic Design

Industry experts have applied baffles in acoustic design to manage sound clarity and control noise interference. The use of these components supports precise sound distribution and meets the demands of businesses seeking reliable acoustic performance.

Case studies highlight improvements in noise isolation and overall system stability, providing measurable benefits in operational performance and sound quality:

- Enhanced sound clarity in large office setups

- Reliable noise control in industrial environments

- Smooth integration with managed IT services

Innovative Uses in Marine Engineering

Marine engineering benefits from the innovative use of baffles that regulate fluid dynamics and control mechanical vibrations. Expert technicians have demonstrated that strategically placed baffles improve the stability of underwater systems and optimize energy distribution in marine settings.

Industry specialists document practical instances where baffles support critical operations on maritime vessels and offshore installations. These engineered components help maintain consistent performance under fluctuating sea conditions, addressing operational challenges with clear and effective solutions.

Lessons Learned From Industrial Applications

Industry experts have observed that using baffles in industrial applications leads to improved system reliability and minimizes operational downtime. Real-world examples demonstrate that proper baffle installation in manufacturing setups helps control noise and vibrations, directly benefiting managed IT services that support high-performance office equipment, such as copiers and printers.

Technical evaluations reveal that baffles effectively manage energy flow in heavy-duty environments, ensuring smooth operational performance. Practical insights from industrial case studies confirm that regular maintenance of baffle systems increases longevity and minimizes disruptions, offering clear solutions to common operational challenges.

Frequently Asked Questions

What is a baffle and its primary function?

A baffle is a partition inside devices that regulates airflow and minimizes noise, ensuring stable operations and protecting sensitive office equipment by reducing vibrations and sound disturbances.

Where are baffles used in different systems?

Baffles are common in HVAC systems, industrial cooling, and water treatment installations. They control fluid flow, reduce noise, and boost efficiency by channeling air or liquid through designated pathways.

What types of baffles suit specific applications?

Perforated baffles work well in noise-control applications, while adjustable types suit ventilation needs in office equipment enclosures. Solid, custom designs are ideal for protecting sensitive components in managed IT service settings.

How do baffles enhance system performance?

Baffles control movement within systems, ensuring regular distribution and minimizing turbulence. This results in improved stability and efficient operation, key for maintaining dependable equipment performance.

What maintenance is recommended for baffles?

Regular cleaning, inspection, and adjustments of baffles are recommended to maintain stability and performance in office equipment. Use manufacturer guidelines when scheduling timed maintenance to reduce repair costs and prevent unexpected breakdowns.

Conclusion

Baffles serve as integral components that control noise and channel energy efficiently in both acoustic and fluid systems. They maintain system stability by strategically managing sound and vibrations, which benefits office setups and industrial environments alike. Their use leads to improved operational performance, higher energy efficiency, and expanded reliability in various applications. The engineered design of baffles offers clear, measurable benefits that drive enhanced performance and longevity in critical systems.